Design Evolution

The designs here represent a selection of secure bag-hanging devices created during the iterative development processes of the ‘Turning the Tables’ Grippa evaluation project, 2006-9. Many more concepts and prototypes were generated, which are not shown here, although the examples below are indicative of key stages during the design, critique, testing and feedback stages. The concepts are organised into sections A-D, according to materials and manufacturing methods.

A: Stainless Steel / Cast Aluminium / Brass

+ virtually any 3D shape achievable

+ permits complex details for hinges, flanges etc.

+ can be polished, powder coated, or alu can be anodised to colour

– more expensive to prototype

– higher mould and set up costs can impact on small-run unit costs

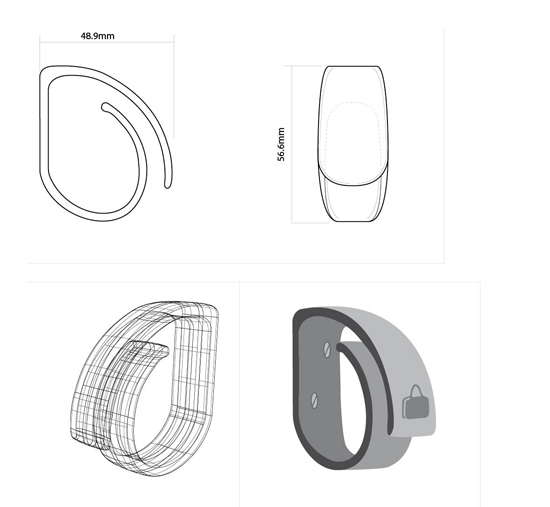

Iteration 5. See also final Design Outputs

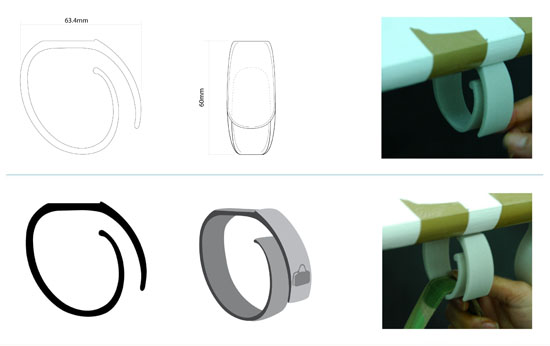

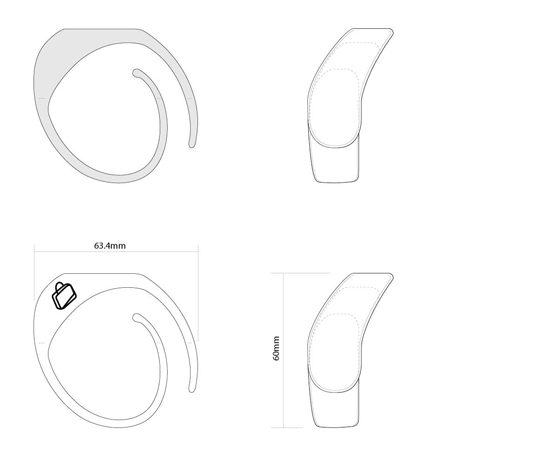

5.1 Curl

Dual Mount (horizontal / vertical): with articulated gate. Accepts 24mm dia. bag straps, open or folded.

![]()

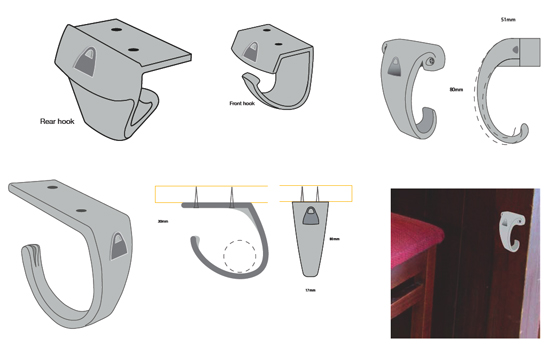

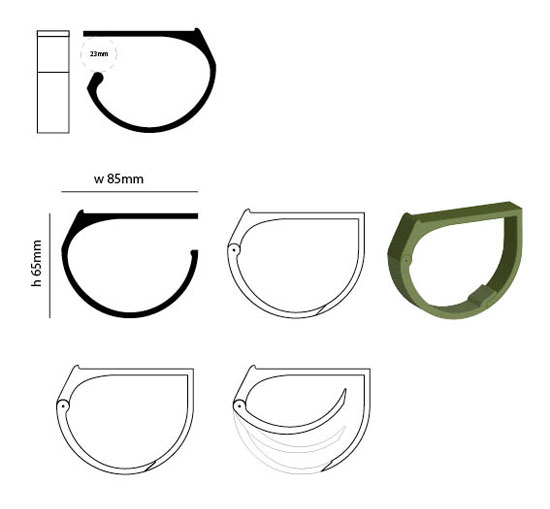

Iteration 4.

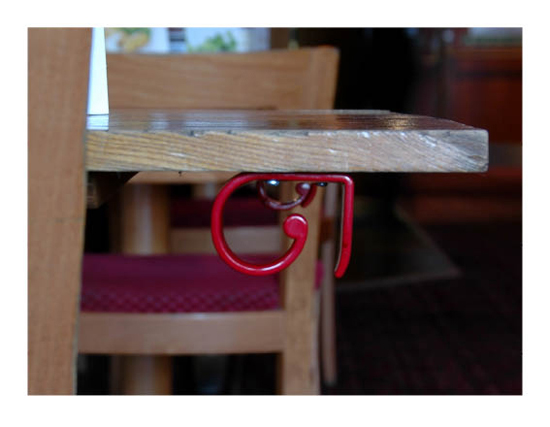

4.1 Snail

Dual Mount (horizontal / vertical): static. Accepts 20mm dia. bag straps, open or folded.

![]()

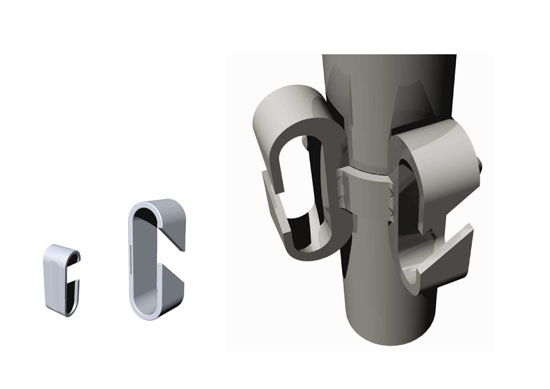

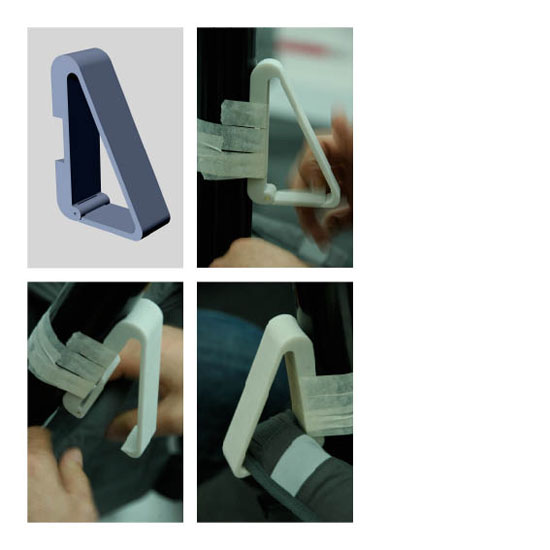

4.2 Lip

Horizontal mount: with articulated gate – accepts 20mm dia. bag straps open or folded

4.3 Twist

Column mount, typically onto table legs (three clips per circle).

![]()

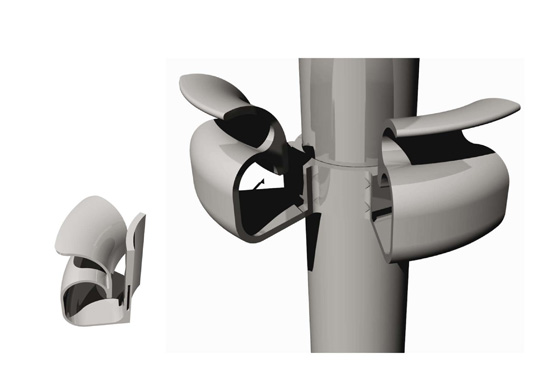

4.4 Poppy

Column mount, typically onto table legs (three clips per circle).

![]()

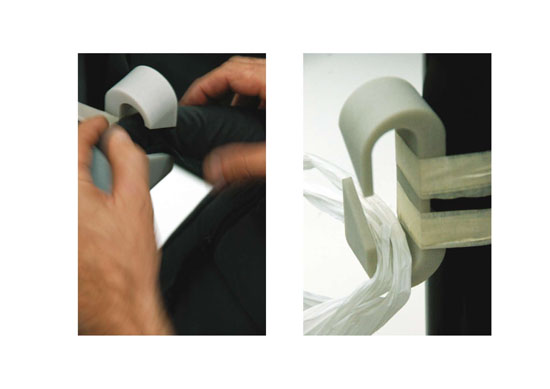

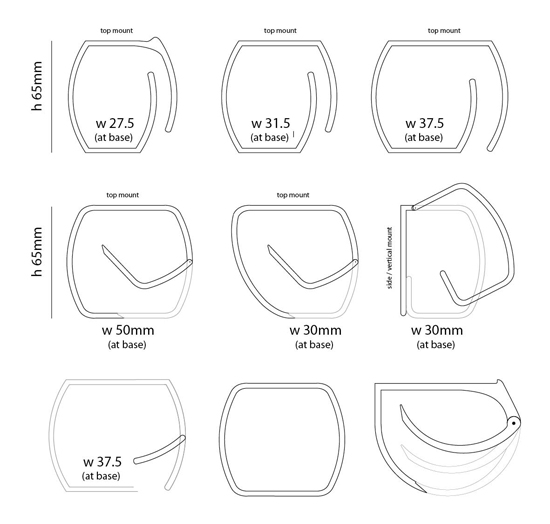

Iteration 3

Iteration 3 user testing workshop.

–

![]()

3.1 Gate

![]()

3.2 Manoeuvre

![]()

3.4 Poppy

![]()

3.6 Horizontal mount, static

![]()

3.7 Vertical mount, static

![]()

3.8 Horizontal mount, with articulated gate, closed by weight of bag

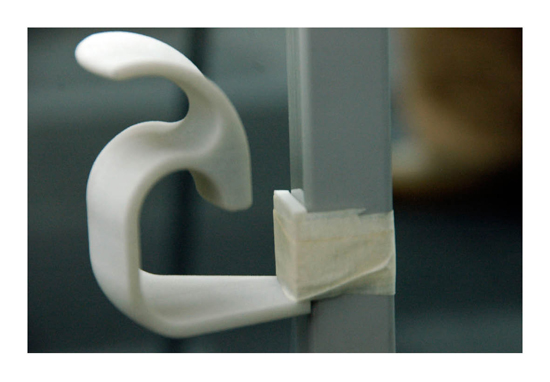

Iteration 2

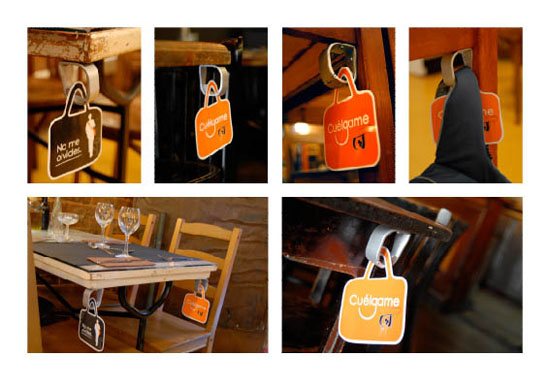

2.9.1 Horizontal mount (under table), static manoeuvre, front orientation allowing graphic/logo space

2.9.2 Horizontal mount (under table), static manoeuvre, side orientation allowing more graphic space

2.9.3 Horizontal mount (under table), static manoeuvre, front and side orientation allowing graphic/logo space

2.7 Horizontal and Vertical mount, static reverse hook

![]()

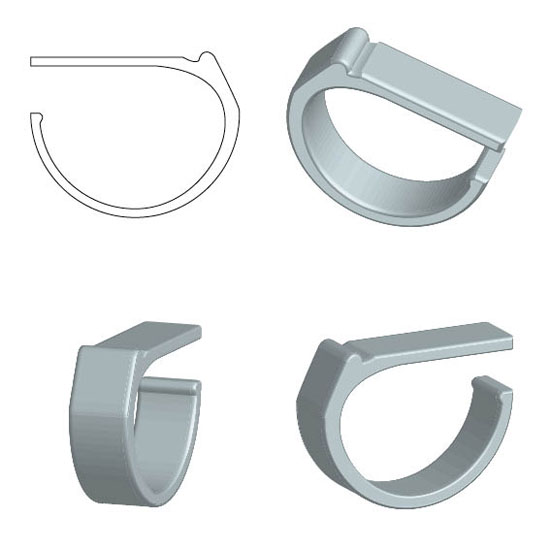

Iteration 1

1.5 variants

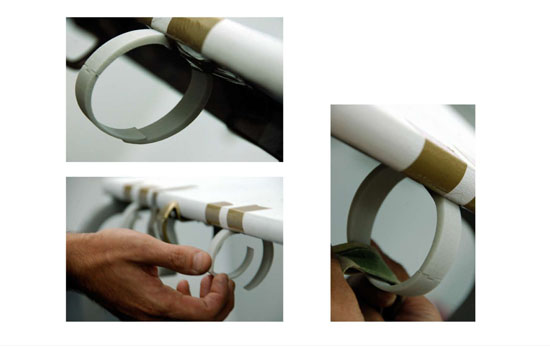

1.2 Horizontal mount, static and articulated

![]()

![]()

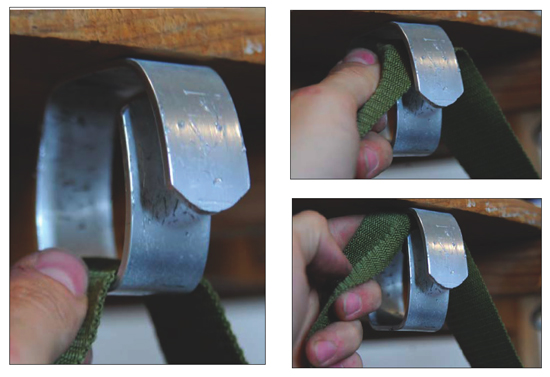

1.0 Grippa 1 clip design (2005). Brass, with Sprung articulated gate.

![]()

______

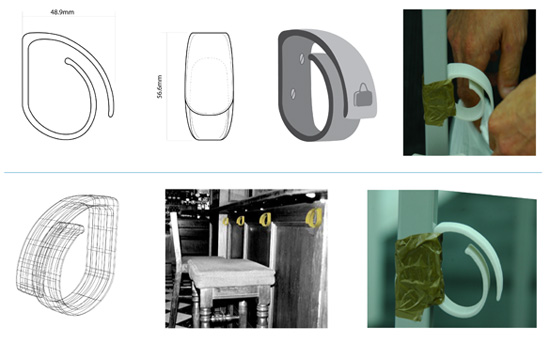

B: Bent Bar

+ simple production in steel or aluminium

+ low material costs

+ economic fabrication in small or large batches

– not well suited to hinge options

– limited ‘3rd dimension’ detailing

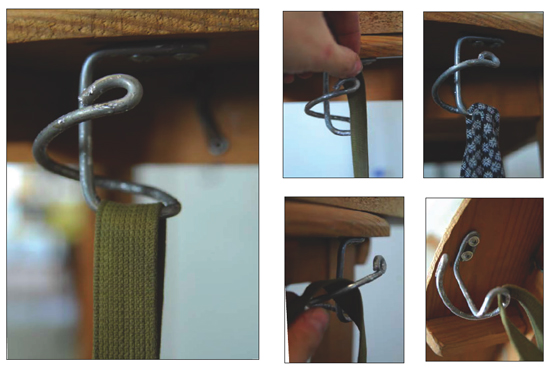

3.5

3.7 bent bar

2.3 bent bar

![]()

______

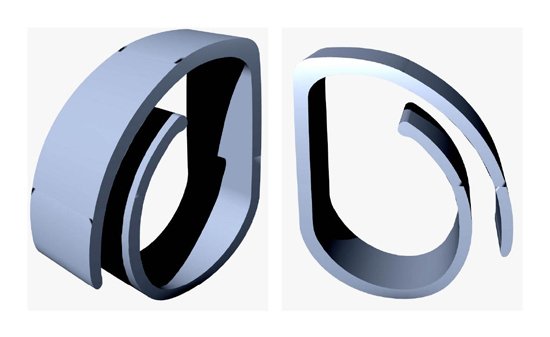

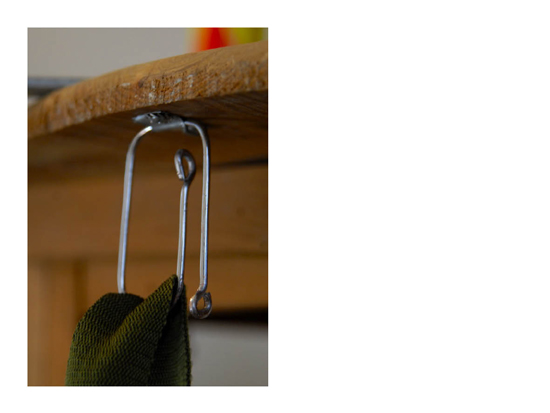

C: Bent Rod

+ simple production in steel or aluminium

+ visually ‘open’/ ‘light’ forms achievable

+ low material costs

+ economic fabrication in small or large batches

– not well suited to hinge options

– limited ‘3rd dimension’ detailing

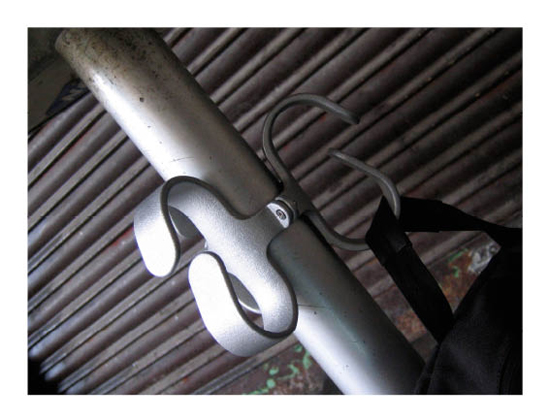

2.5

2.6

![]()

______

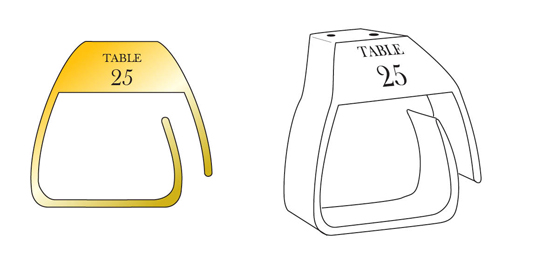

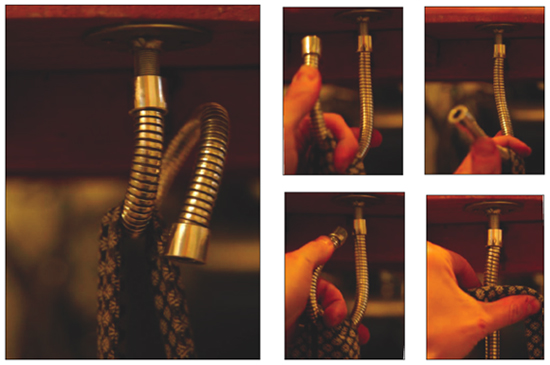

D. Other Investigations

![]()